Services

Dynamic analysis of pile driving

PDA CONSULTANTS INC. has also carried out dynamic pile driving analyses on unusual types of foundation, such as GEWI piles or sheet piling. In addition to being used for new construction, dynamic pile driving analyses can also be carried out on existing piles to provide expert assessments of existing deep foundations. Dynamic pile driving analysis can be used in preliminary design studies to optimize the type of deep foundation to be used, the length of piles in the ground and construction costs. The use of a test rig or continuous pile driving is one way of acquiring a number of important data for this optimization.

In addition, pile-driving equipment can be calibrated by adjusting the energy measured with the pile-driving analyzer to the energy indicated on the computer inside equipment fitted with a hydraulic hammer.

The use of the pile-driving analyzer can also give rise to other specific applications, such as evaluating the energy transmitted to a split core barrel (SPT) during exploratory drilling for geotechnical studies. Evaluation of this energy using the pile-driving analyzer enables us to adjust the values obtained in the field according to the actual energy transferred to standardized N60 values in compliance with ASTMD1586 “Standard Penetration Test (SPT) and Split-Barrel Sampling of Soils” in force.

CAPWAP analysis is used to assess the total capacity of a pile, as well as the distribution of strength along the shaft and at the pile tip. It can also be used to estimate a pile’s pull-out resistance following a dynamic loading test.

The engineering team at PDA CONSULTANTS INC. also offers deep foundation monitoring, training and consulting services, as well as sonic concrete testing (CSL or TIP). Contact us today to take advantage of our services.

Sonic auscultation testing

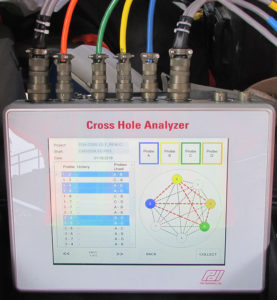

Cross Hole Sonic Integrity Logging (CSL) tests verify the quality and uniformity of concrete placement inside the reinforcing cage of a caisson or secant wall. Sonic testing is carried out in accordance with ASTMD6760 “Integrity Testing of Concrete Deep Foundations by Ultrasonic Crosshole Testing”.

The transmission of ultrasonic pulses in the concrete from one probe to the next enables the integrity of the caisson structure to be inspected. Combinations of the profiles inspected can be used to locate and determine the extent of any defects, imperfections or anomalies.

Caisson integrity assessment considers the increase in the arrival time of the signal emitted by the transmitting probe at the receiving probe, i.e. the “First Arrival Time (FAT)”, and the attenuation of the signal energy, relative to the signal arrival time or energy in the adjacent area of sound concrete.

The quotient of the distance between transmitter and receiver by the FAT value estimates the wave propagation speed, which is also a relative indicator of concrete quality.

Proper installation of the test tubes is essential for sonic concrete testing and data interpretation. When these tubes are equidistant and parallel to each other, and the concrete inside the box is uniform between the test tubes, the FAT should be regular and therefore present a more constant wave velocity with good signal intensity. For non-uniform concretes, with contamination, dimples, voids or inclusions, the signal shows delays in arrival time and signal intensity is reduced.

This method of sonic testing of concrete does not give the exact nature of a defect, but rather an assessment of the quality of the concrete in place. The method is limited to the concrete between the auscultation tubes and the depth inspected, i.e. the depths accessible simultaneously by the CSL probes, between the pair of tubes defining the section. No conclusions can be drawn from tests on the portion of the section below the auscultation tubes and outside the reinforcement cage.

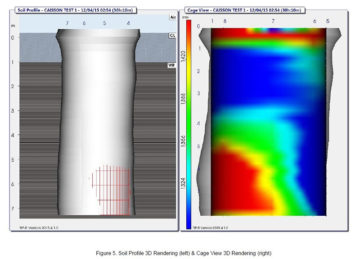

Thermal Integrity Profiling (TIP) testing uses the heat of hydration produced during curing of the concrete mix to assess the integrity or quality of concrete within deep foundations. Thermal integrity profiling tests are carried out in accordance with ASTMD7949 “Thermal Integrity Profiling of Concrete Deep Foundations”.

Since the tests are based on the temperature generated during concrete curing, TIP tests should generally be carried out between 4 and 72 hours after concrete placement. The maximum heat of hydration measured by the thermocouples in the caisson varies according to the diameter of the caisson, the type of mix used, the location of the reinforcement cage in relation to the center of the caisson, and the time elapsed between placing the concrete and taking the measurement. These factors can vary the average temperature recorded by sensors located at the same elevation in the caisson.

Measurements taken during thermal profiling integrity tests enable us to estimate the actual shape of the caisson. These estimates can be compared with notes taken on site during concrete placement, to confirm the overall quality of the concrete inside the caisson.

A reduction in temperature (colder than average) may indicate a reduction in casing diameter, water ingress or poor-quality concrete.

An increase in temperature (warmer-than-average region) may indicate a higher bulge or overlap of the reinforcing cage.

A temperature difference between sensors located at the same level and diametrically opposed may indicate a problem with the alignment of the reinforcing cage, or a problem with the concrete cover around the reinforcing cage.

Unlike CSL testing, thermal profiling integrity testing enables us to analyze the entire cross-section of a caisson, including the area outside the reinforcing cage. What’s more, thermal profiling integrity tests are not affected by winter weather conditions. In fact, the water management required for CSL testing can prove complex when these tests are carried out at sub-freezing outside temperatures.

The engineering team at PDA CONSULTANTS INC. also offers dynamic pile-driving analysis (PDA testing), deep foundation monitoring, training and consulting services. Contact us today to take advantage of our services.

Deep foundation monitoring, training and consulting

PDA CONSULTANTS INC offers a deep foundation monitoring service that includes pile driving, monitoring of static loading tests, and monitoring and control of the installation of anchors. Monitoring and control of deep foundation work are inexpensive ways of ensuring the quality of structures by preventing or remedying problems relating to work execution, and ensuring that deep foundation work complies with the requirements of plans and specifications.

The control and monitoring of pile driving provides relevant project information. This type of control makes it possible to monitor the progress and progress of pile installation, to ensure compliance with requirements. The integration of a pile driving logbook at the start of the project provides information on pile driving dates, re-driving dates, identification of driven piles, pile physical characteristics (diameter, wall thickness, pile length and inclination) and location characteristics.

A visual inspection of the structural integrity inside the piles is also carried out when closed-end tubular steel piles are used. In addition, verification and monitoring of the rejection criterion established during dynamic loading tests is information that the design engineer must receive periodically in order to make the necessary suggestions and corrections to ensure that the work proceeds smoothly.

Conventional static loading tests, whether compressive, pull-out or lateral, are also used to ensure the quality of deep foundation structures. Depending on the requirements and information needed, different loading methods can be used. The most commonly used loading methods are the step or cyclic method, in accordance with current ASTM standards. During the monitoring of these tests, information on the loads applied and the pile displacements, as required, is passed on to the design engineer, so that he or she is able to understand the behavior of a pile following the stresses to which it has been subjected.

Monitoring and control of anchor tests are based on the same methodology used for static pull-out loading tests. During the monitoring of these tests, information concerning the loads applied and the elongation of the tie rods, as required, is passed on to the design engineer, so that he or she is in a position to understand the behavior of the structure in response to the stresses to which it has been subjected.

Training and consulting

The expertise of PDA CONSULTANTS INC. enables our engineers to offer specific training or consulting in the field of quality control of deep foundations, to our customers and to various government agencies.

In fact, PDA CONSULTANTS INC. can provide presentations on specific deep foundation topics to suit your needs. Whether it’s dynamic pile driving analysis, sonic concrete testing (CSL), TIP testing or deep foundation monitoring, we can meet your needs. Contact us today to take advantage of our services.